PT. Astra Daido Steel Indonesia

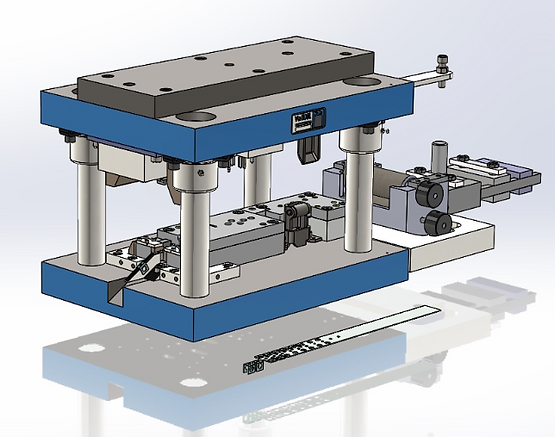

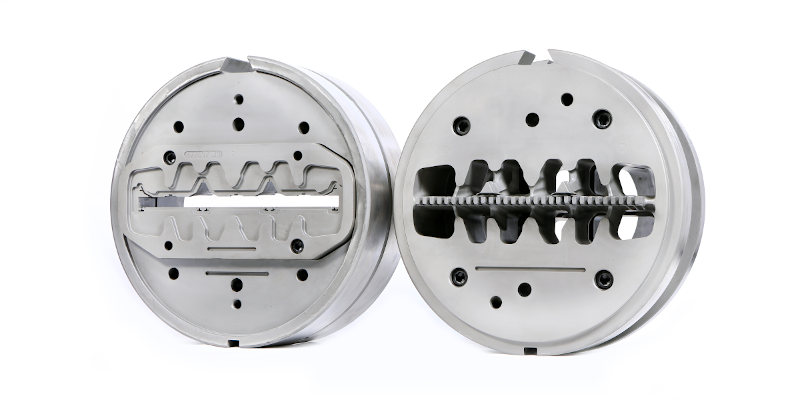

One-Stop Solution

PT Astra Daido Steel Indonesia is a synergy between PT Astra Otoparts Tbk, a leading company in the automotive sector in Indonesia with Daido Steel Co., Ltd and Daido Die & Mold Steel Solutions., Co., Ltd. leading company in Japan as a quality tool steel manufacturer. The Quality of tool steel produced by PT Astra Daido Steel Indonesia has been recognized throughout the world and has been proven by manufacturing industry.